MECHANICAL DESIGN OPTIMIZATION

The key to effective optimization is the ability to rapidly explore alternatives — a task at which Enventive Concept excels.

Changing dimensioning schemes is fast and easy and doesn’t require model rework. Parameter values can be changed directly from the tolerance analysis report, and re-analysis is automatic. Both parameter and tolerance optimization can be driven directly from the tolerance analysis report. Enventive Concept’s ability to rapidly explore alternatives is hundreds of times faster than that of competitive tools.

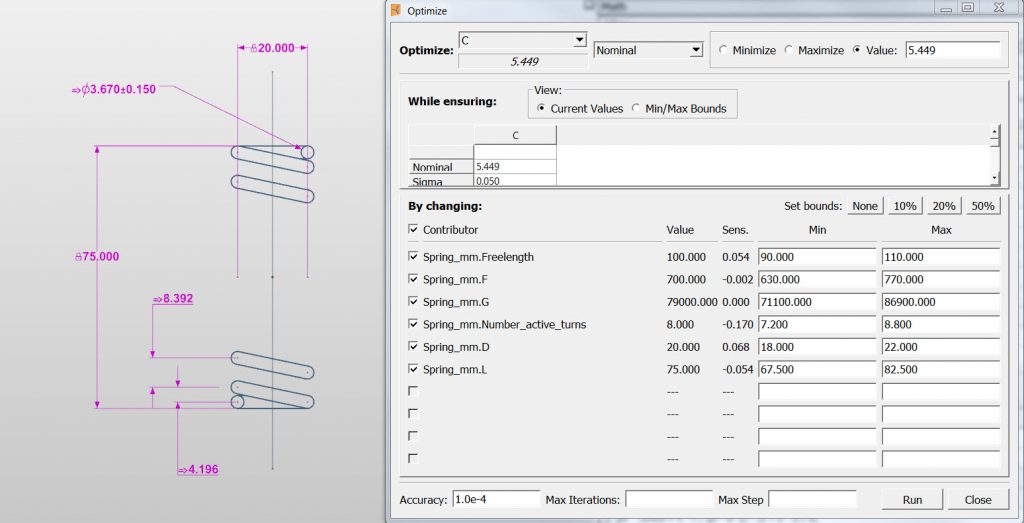

Enventive Concept is the only mechanical engineering tool that provides optimization of both parameters and tolerances directly from a tolerance analysis report. Users can simultaneously optimize up to 200 parameters with up to 500 constraints on the values of those parameters.

For example, you could optimize the parameters of a spring (wire diameter, spring diameter, number of turns, and free length) to produce a specific force-deflection relationship, with minimal variation, simultaneously with a constraint that specifies the shear stress must be less than the endurance limit.

Further reading on our tolerance analysis software

Back to Enventive Concept

Check out the latest Enventive Concept news

Learn about our other products: Enventive 3D&T and Enventive 360