Are you a mechanical engineer or designer in manufacturing? Or managing a mechanical design group? If so, you very likely do tolerance analysis with 1D stackups of component assemblies using spreadsheets and/or with 3D software tools.

If your business has experienced costly production or warranty problems related to product tolerances and/or are pursuing continuous improvement of your engineering design processes, you may be asking the following question:

Are 1D spreadsheets and 3D tools enough to get maximum value out of our tolerance analysis projects?

This resources section of our website helps you answer this question by exploring the what, why, and how of tolerance analysis for manufactured products that are mechanical assemblies. We’ll overview 1D spreadsheets, 2D tools, 3D tools, and additional options for tolerance analyses. To ensure a baseline understanding of key concepts, we’ll go over a few basics that you may already know. On this introductory page we cover these topics:

- What is tolerance analysis and why is it needed?

- What products need tolerance analysis?

- How to do tolerance analysis?

- What is functional tolerance analysis?

- What are the benefits of tolerance analysis?

WHAT IS TOLERANCE ANALYSIS AND WHY IS IT NEEDED?

Tolerance analysis, also known as variational analysis, is for determining how much a manufactured product’s components can vary in their dimensions and geometry (in other words their tolerances, which is also referred to as their tolerancing) and still work together as intended. The analysis can involve one or more techniques that depend on the type of and complexity of the product.

When referring to dimensions, we’re referring to the size of component or assembly between two opposite points in a particular direction, like its length or width. For geometries, we’re referring to factors such as form (e.g. flat or curved), orientation, position, run-out, concentricity, and so on.

Why is tolerance analysis needed?

For many mechanical products in a wide variety of manufacturing industries, tolerance analysis is an important part of the design process to ensure that product components made on different machines, or by different suppliers, or at different times, all work well together. This is especially important when producing items in high volumes where individual variations in dimensions and geometries may not be noticeable at first but start to creep in over time and then add up to create problems with assembly or performance of the product to its requirements.

So the designer must choose tolerances that are precise enough for each component to avoid assembly or performance problems. On the other hand, precision adds to the costs of manufacturing. Choosing the right tolerancing is not a trivial task even for simple assemblies.

Tolerance analysis history

The evolution of tolerancing and tolerance analysis goes back to the earliest days of interchangeable parts for manufactured products — for example in the 1700s the notion of what a French general called the “uniformity principle” in parts for military equipment contributed to the rapid disassembly and reassembly of light artillery for greater mobility.

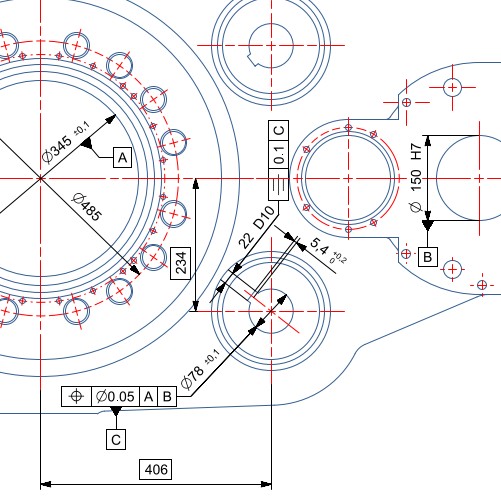

Standardization of tolerance representation on engineering documents and formalization of tolerance analysis methods started to accelerate with the emergence of mass production of automobiles and other mechanical products in the early 1900s. In particular, the concept of Geometric Dimensioning and Tolerancing, or GD&T, gained widespread use during and after World War II. This is a symbol-based markup language that defines and communicates tolerances by describing nominal values of part dimensions, geometries, and their allowable variations. Clear understanding of this language has become globally critical to the successful design, manufacturing, and control of mechanical products.

To learn more about GD&T, please visit our resource page: "What is GD&T?"

Two major standards for GD&T markups are ISO’s Geometric Product Specifications (GPS) and ASME’s Geometric Dimensional and Tolerancing (GD&T). GD&T markups are core to the 2D and 3D engineering drawings needed to manufacture parts and are essential to modern tolerance analysis.

WHAT PRODUCTS NEED TOLERANCE ANALYSIS?

You’ll find tolerance analysis to be an integral part of the design process for mechanical products in industries such as automotive, aerospace, appliances, medical, military, industrial machinery, and even luxury goods for watches.

Products with mechanism components that move, such as levers, cams, rotating elements, and springs especially benefit from in-depth tolerance analysis.

Examples of mechanical products that typically make use of tolerance analysis include:

- Gear assemblies

- Automotive latches

- Electric motors

- Engines

- Brake assemblies

- Pumps

- Compressors

- Valves

- Robotic devices

- Medical devices

- Electric switches and breakers

In summary, mechanical products for which their parts must fit together precisely to function correctly are improved with tolerance analysis.

HOW TO DO TOLERANCE ANALYSIS?

The tolerance analysis approach and methods you use will, of course depend on the nature and complexity of your product as well as the scope of an analysis.

Originally tolerance analysis focused on ensuring the fit of an assembly’s components so that those components could be reliably assembled. The analysis takes into account potential geometric and dimensional variations of each component as they are combined into stackups. Typically this type of tolerance analysis takes place late in a design cycle, after a detailed design is almost completed and available as 2D and 3D drawings created within a computer-aided design (CAD) system. The primary goal is to validate that the tolerance values specified by the design engineer result in an acceptable fit of an assembly so it can be manufactured.

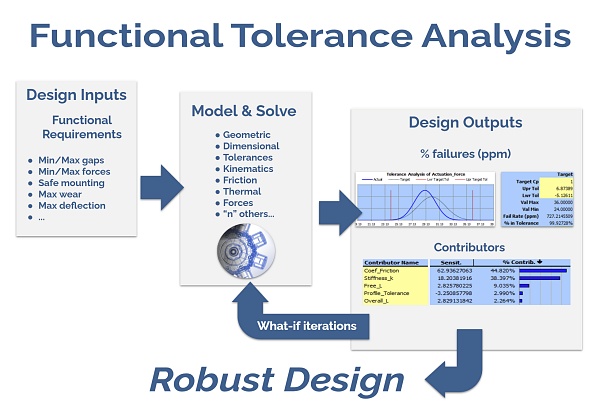

In the 1980s, the idea of tolerance analysis going beyond just validation of fit was introduced. The idea expanded tolerance analysis to consider impacts on a product’s ability to deliver its functional requirements, such as level of forces, range of motion, or flexibility of a part. This type of tolerance analysis of a complete assembly is known as functional tolerance analysis, which this article covers in more detail below.

With functional tolerance analysis a designer creates a functional model of a design that enables evaluation of the design’s tolerance values in combination with nominal geometric and dimensional values. The analysis can start before a 3D CAD design begins and continue on during the 3D design work, including the same validation of fit provided by traditional tolerance analysis methods.

Whether you are undertaking traditional or functional tolerance analysis, almost always software programs will be the starting point. Component geometries and dimensions are modeled so their tolerances can be analyzed and decisions made. After analysis and creation of detailed 2D and/or 3D drawings within a CAD system, commonly one or more prototypes will be created to further assess tolerance values and other aspects of a design.

1D, 2D, or 3D?

For the overall tolerance analysis approach, whether it is traditional and/or functional, you can choose to work in 1D, 2D, or 3D, or a combination.

For straightforward linear stack-ups of components assembled in one direction, 1D analysis is a common choice. Spreadsheets, such as those built with Microsoft Excel, are frequently used.

As the complexity of a product’s components increases beyond fairly simple linear stackups, such as with motion, cams, levers, and springs, you’ll want to strongly consider working in 2D and/or 3D. For most mechanisms, Enventive’s experience is that 2D is a very effective modeling approach. It lends itself to rapid and intuitive representation of geometric, dimensional & tolerancing (GD&T) parameters.

2D functional tolerance analysis products, like Enventive’s Concept software, quickly report on the location and likely rates of potential failure modes across a series of GD&T parameter iterations. Through what-if analysis engineers can quickly narrow down their design choices and make optimal GD&T decisions.

With 3D tolerance analysis, you have the most true-to-life GD&T representation of a product and its components. But you also have much more model complexity than with 2D, making it very difficult or even impractical to do rapid iterations of GD&T parameters. However as product design drawings near being finalized within a 3D CAD system, 3D tolerance analysis can be a very effective tool for validating the GD&T choices to be made when 2D models are not sufficient, such as when 3D spatial effects are important to deliver on functional requirements.

In fact with Enventive’s Concept product for 2D tolerance analysis, a common design process is to first complete a 2D functional tolerance analysis entirely in Concept and then transfer the GD&T design results into a new 3D CAD model. From those 2D GD&T results the 2D and 3D drawings needed for manufacturing can be completed much more quickly and confidently within a CAD system than with no 2D analysis.

Another common 2D tolerance analysis process is to identify existing 3D CAD model cross sections where functional conditions must be analyzed, and then export them with their GD&T values back to a 2D analysis tool, like Enventive Concept, for validating design choices and making any needed changes. In this case Concept is being used for functional tolerance analyses in as many different planes as needed.

For an in-depth review of these three options, please visit our resource page: "When to use 1D, 2D, and 3D tolerance stacks?"

Tolerance analysis calculation methods

Whether you are working in one, two, or three dimensions, there are several stack-up calculation methods commonly used to assess failure modes and rates. These include stackups of worst-case scenarios as well as statistical techniques such as root sum square (RSS) and Monte Carlo simulation.

Worst-case methods determine the maximum possible geometric or dimensional deviations within an assembly by summing the worst-case variations of each part.

So for instance if each part’s parameter was reaching the upper limit of its tolerance range, the worst-case assembly functional condition would be similarly at its limit, which could be a failure mode.

Instead of assuming the worst, which can lead to overly tight tolerancing, statistical techniques estimate the probability of combined part variations leading to a failure, such as an assembly being too loose or tight relative to specification. Two very common methods are RSS and Monte Carlo simulation.

RSS assumes a normal statistical distribution for each component’s geometric and dimensional values. By combining the means of the components parameters and applying the root sum of squares equation to the standard deviations, this method estimates the variation for an entire stack of components and the failure rate versus requirements.

RSS has proven to be a fast and effective calculation method for analyzing combined tolerances for most mechanical systems, such as for mechanisms.

Integral to RSS methods are the use of Cp, Cpk, and PPM, which are statistical calculation parameters that together enable greater insights into which part variations are driving failure rates.

For a detailed description of statistics for tolerance analysis, please visit our resource page: "What are Cp, Cpk, and PPM in Tolerance Analysis?"

For more complex mechanisms that are difficult to calculate using RSS, Monte Carlo simulation is widely used. Instead of normal distributions, Monte Carlo represents component variations with random numbers. It runs a number of trials using these random numbers, often in the thousands of trials, to determine a probability estimate that the assembly will fail to meet requirements.

For an in-depth overview of these calculation options, please visit our resource page: "What are Worst Case, RSS, and Monte Carlo Calculation Methods and When to Use them in Tolerance Analysis?"

Datums

Datums, which are theoretical points, lines, or planes from which measurements are made, are one of the building blocks of tolerance analysis as well as for GD&T. Using datums, mechanical designers define: a) the nominal geometries of parts, and b) the location and orientation of the tolerance zones within which a part’s actual surfaces must lie.

A designer’s goal with the specification of datums is to conceptually remove the six modes in which a part can independently move (three linear and three rotational) — in other words to suppress its degrees of freedom. By doing this the datums guide the tooling needed for fabrication of parts and then the measurement of those parts and their assemblies to ensure correct fit and expected functional performance of the manufactured product.

The representation of datums are core to supporting GD&T design decisions and to tolerance analysis software products, such as Enventive Concept.

For more about what datums are and their importance to tolerance analysis, please visit our resource page: "Why are GD&T Datums Important to Tolerance Analysis?"

WHAT IS FUNCTIONAL TOLERANCE ANALYSIS?

Earlier in this article, we overviewed tolerance analysis mostly from the perspective of ensuring that tolerance values enable individual components within a mechanical product to fit together as intended — for example not so tight that it cannot be assembled. We refer to this as traditional fit-for-assembly tolerance analysis, which typically takes place late in a design process.

While ensuring fit for assembly is of course critical, making sure that a product’s functional requirements are met is also critical. A designer also needs to determine the range of allowable variations in the geometric and dimensional values of components that do not interfere with the product’s functionality. This is where functional tolerance analysis comes in. This type of analysis can tell you, for example, whether or not an assembly has enough clearance for a desired motion, such as the rotation of an electric motor driven cam system. It is quite possible that the assembly has enough clearance to be assembled, but not enough to reliably meet the functional requirement of a specific motion.

Another type of functionality commonly analyzed is force. For example in a mechanical latch, such as in an automobile door or seat, making sure that the forces to open and close the latch meet design requirements is critical to safety and usability. Because the latches are small and with cams, levers and springs, even small geometric and dimensional variations in their components can lead to a failure in meeting functional requirements. This is an example of a product’s performance to requirements being highly sensitive to component variations, which is a very common design issue for engineers. Functional tolerance analysis will model those forces as the latch mechanism moves versus candidate GD&T values to help a designer iteratively make optimal decisions for those values.

Enabling robust design

With functional tolerance analysis, engineering designers have a powerful tool for iteratively making GD&T design decisions that ensure that a product will function as intended under a broad set of conditions, especially extreme conditions. This approach is known as robust design.

For example an engineer might need to ensure that a mechanism meets functional motion requirements across a wide range of operating temperatures, input forces, or gaps between components.

With robust design, a product can achieve higher and more predictable levels of reliability than otherwise possible. To reach targeted levels of reliability, designers systematically work through a product’s functional failure modes until they can be eliminated through GD&T decision making. This aspect of a robust design process is what is known as Failure Modes and Effects Analysis, or FMEA.

WHAT ARE THE BENEFITS OF TOLERANCE ANALYSIS?

Tolerance analysis tools save time and money by helping to design, build, assemble, and test products more effectively and robustly. The tools also help avoid expensive rework late in a product development process and once the product is in production.

Traditional tolerance analysis tends to benefit late design phases through validations of assembly fit.

Functional tolerance analysis, when used at the very beginning phase and during later phases, can cut time for design completion and getting to market. It helps engineers to identify problems early in the design process, when changes can be more easily made without affecting existing components or systems elsewhere in the product.

Design and prototyping benefits

For prototyping, tolerance analysis yields design results that are much closer to being production ready versus designs done without tolerance analysis. It finds “no-fit” or misfit conditions before prototypes are built so that defects can be corrected first rather than discovering them during prototype testing. Tolerance analysis also finds “high fit” conditions where components fit together too tightly for cost-effective assembly, enabling tolerancing changes that improve manufacturability or better accommodate variations during assembly. This all leads to fewer needed prototypes, lowering costs and saving time.

For functional tolerance analysis, design and prototyping benefits include and go beyond fit-based tolerance analysis. For example a global manufacturer of automotive components, U-Shin, finds immediately payback for redesigns of automobile latches. Using Enventive’s Concept software for functional tolerance analysis, the company’s engineers find they can complete robust redesigns that take into account required forces and are ready to go to production within five days versus what had been taking four weeks with traditional 1D tolerance analysis based on spreadsheets. They are also able to cut the number of needed prototypes to one or two versus eight to ten with spreadsheets.

For more details see Enventive’s case study for U-Shin.

Because functional tolerancing analysis models with tools like Enventive’s Concept software create comprehensive 2D GD&T representations of a design, once a model is built design engineers can save time by reusing that model over and over again to analyze fit and functional requirements across different stack-ups. The result is one model for many analyses. Attempting to do similar analyses using 1D tools like a spreadsheet requires separate tabs and can be much more time consuming.

Production benefits

For production, tolerance analysis identifies design problems that could result from dimensional variations that can occur for reasons such as manufacturing equipment wear. Resolving these kinds of problems before a design is complete and before production kicks off, helps to prevent costly rework that can slow down the product’s launch or that can lead to excessive warranty claims.

For example, one of the world’s leading producers of power and garden tools, Bosch’s Power Tools division, finds that functional tolerance analysis with Concept leads to fewer warranty claims through an improvement of 15% in field quality.

For more details see Enventive’s case study for Bosch Power Tools.

DFSS Benefits

Functional tolerance analysis is a key tool enabling Design For Six Sigma (DFSS) approaches to mechanical products. DFSS principles are applied by major manufacturers throughout the world as a methodology for accelerating design cycles and improving product quality.

Key steps of DFSS include:

- Identifying critical parameters early in the design process (these are the variables that control the functions of a design)

- Optimizing the critical parameter values to reduce sensitivities to variances in components

- Determining the tolerance requirements for the critical parameters

- Choosing manufacturing processes that can reliably deliver the tolerance requirements

- Proceeding with detailed design based on the optimal values of critical parameters and the manufacturing processes to produce them

Functional tolerance analysis, with its ability to model the relationships between GD&T values and the functional characteristics of a design, fills the gap between critical parameter decision making and ensuring manufacturability. With functional tolerance analysis, engineering organizations have a technique for more fully benefitting from their DFSS processes.