ENVENTIVE® 3D&T

3D Tolerance Analysis Software

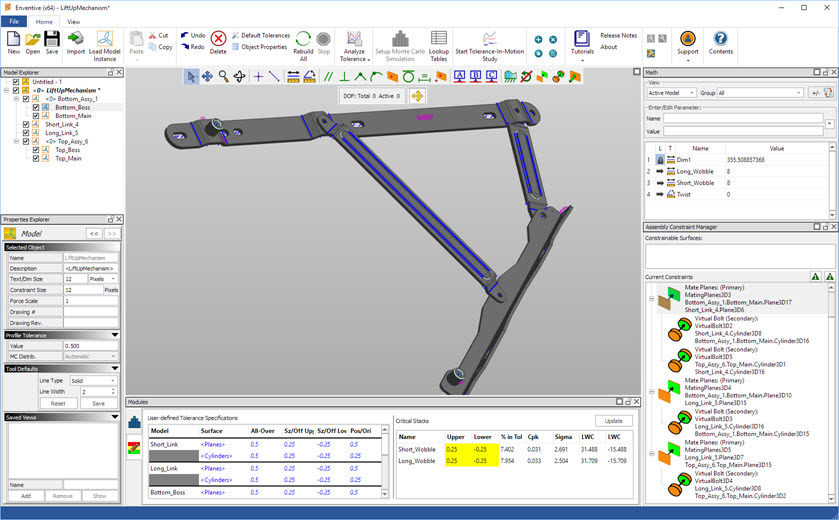

Turn your CAD models into 3D variational models. Optimize all your tolerance analyses in minutes for best-in-class GD&T on 3D annotations.

Simple yet powerful, any designer or engineer can ensure that all product functions are achieved with the best balance between cost and quality.

IMPORTANT SOFTWARE UPDATE

Enventive 3D&T is currently under development and in alpha testing. For updates we invite you to follow Enventive’s LinkedIn page or Contact Us.

WHY DEVELOP 3D TOLERANCING SOFTWARE TODAY?

With Industry 4.0 driving game-changing technological improvements, manufacturers show increasing interest in Model Based Definition. To convey the Product Manufacturing Information, and especially GD&T, they need to rely more on the 3D annotations in CAD rather than on 2D drawings.

THE PROBLEM IS THAT GD&T is variational and 3D CAD models are not.

Powerful 3D variational software has been on the market for years, but users report that the software requires specialists and using them takes significant time. Product designers and engineers need to solve complex 3D variation analysis, but also recognize that 80% or more of their need is to analyze simple stacks that can be done with 1D stack analysis in a spreadsheet like Microsoft Excel. They recognize that the approach is inefficient, because it’s manual (subject to mistakes) and takes time, while contributing little value (no consideration for geometric tolerancing).

WHAT WOULD BE THE BEST 3D TOLERANCE ANALYSIS SOFTWARE?

The best 3D tolerance analysis software:

- Combines power, simplicity and speed.

- Synchronizes GD&T information with 3D annotations in CAD.

- Provides versatility by solving 1D and 3D stacks and offering a variety of analysis methods, including RSS, Monte Carlo, and Worst Case.

Enventive 3D&T does all this and more.

ENVENTIVE 3D&T TOLERANCE ANALYSIS IN THE FIELD

The pressure is on to commit to your design and launch tooling without delay. You need to create 2D drawings or 3D annotations, but how can you be certain the GD&T on critical features of your solid model will reliably deliver the functional performance you need? Are tighter tolerances really needed? Should you pick other datums to limit costly manufacturing measurements?

Bring your CAD assembly into Enventive 3D&T to instantly turn your model into a 3D variational model. Everything is in place, including your assembly tree. It only takes you a few minutes to make your variational hypothesis: select datums, pick advanced joint functions, etc. From there, you get the full power of Enventive’s mathematical solver.

- Instantly run single or multiple stackup analyses and optimize the stacks easily.

- Use the tolerancing methods you prefer: RSS, Worst Case, or Monte Carlo simulation.

- Perform stackup iterations and get immediate results on the changes you make.

KEY BENEFITS

Enventive 3D&T analyzes static position for mechanisms that have multiple planes of action, gap variation between components, adequate clearance between housings and internal systems, etc.

For example, you can analyze a handle fitting into a door; gaps between a PCB and its housing; fitting pipes together in exhaust systems; molded parts; interlocking static parts (without hinges); and similar applications.

Easy to use by any product designer or engineer, Enventive 3D&T keeps analysis in the hands of those who know the design best.

It gives you immediate answers on how design, datum, and tolerance choices impact functional reliability, so you can achieve your desired quality level.

Enventive 3D&T does all the calculations for you, identifying and ranking the effect of each contributor, so you can clearly understand the impact of key contributors.

Our ground-breaking, innovative 3D CAE solution will empower you to perform mid- to late-stage tolerance analysis and variation optimization on CAD solid models. This will help you secure a robust design and gain confidence successfully anticipating manufacturing issues that previously resulted from tolerance variations.

PRODUCT HIGHLIGHTS

ENVENTIVE 3D&T STORY

Developing 3D tolerance analysis software has been part of the Enventive roadmap from the beginning. Our flagship product, Enventive Concept, is extremely powerful and valuable for developing robust products and significantly reduces costs associated with non-quality. However, 3D&T delivers in areas that Enventive Concept cannot, including:

- Mastering the positioning of parts or sub-assemblies in a 3D environment, such as air vents in a car dashboard or a PCB in its housing.

- Quickly solving low-severity simple stacks. We have often seen users going back to using Excel 1D stacks for these basic applications. The problem is, using Excel still takes considerable time for little value.

WHY NOT INTEGRATE ENVENTIVE 3D&T INTO CAD SOFTWARE?

CAD software is designed to deal with nominal values. Adding a layer for variational computation inside CAD requires users to do complex manual work to try to explain to a non-variational model how to become one. Initially, users may be willing to attempt this, because they expect full model synchronization, but they soon realize that this level of work requires a specialist.

As FEA software, Enventive 3D&T is independent of CAD and avoids the programming limitations that complicate the user experience. In addition to ensuring a direct link with any CAD system, our 3D tolerancing software delivers maximum variational power combined with the best user experience: fast and simple. This is a completely new approach to 3D variational analysis as we know it today.

Further reading on our tolerance analysis software

Check out the latest Enventive 3D&T news

Learn about our other products: Enventive Concept and Enventive 360