TOLERANCE ANALYSIS RESOURCES

What is Tolerance Analysis? Why is It Needed? How to Do It?

An introduction to the what, why, and how of tolerance analysis for manufactured products based on mechanisms. Topics covered include:

- What is tolerance analysis and why is it needed?

- What products need tolerance analysis?

- How to do tolerance analysis?

- What is functional tolerance analysis?

- What are the benefits?

When to Use 1D, 2D, and 3D Tolerance Analysis?

Learn about 1D, 2D, and 3D stack-up modeling and analysis options, their differences, when to use them, and their tradeoffs for tolerance analysis. Here’s the contents:

- What is 1D stack-up tolerance analysis?

- What is 2D stack-up tolerance analysis?

- What is 3D stack-up tolerance analysis?

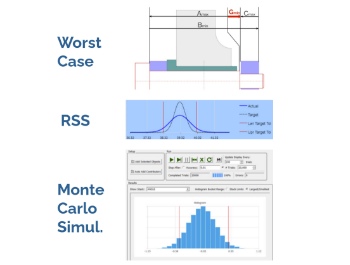

What are Worst Case, RSS, and Monte Carlo Stackup Calculation Methods?

Which method(s) to use depends on factors such as how critical a stackup is, how many components, or the complexity of geometries. This article overviews:

- Worst-case stack-up calculations

- Statistical stack-up calculations

- RSS stack-up calculations

- Monte Carlo simulation stack-up calculations

- Additional stack-up calculation methods

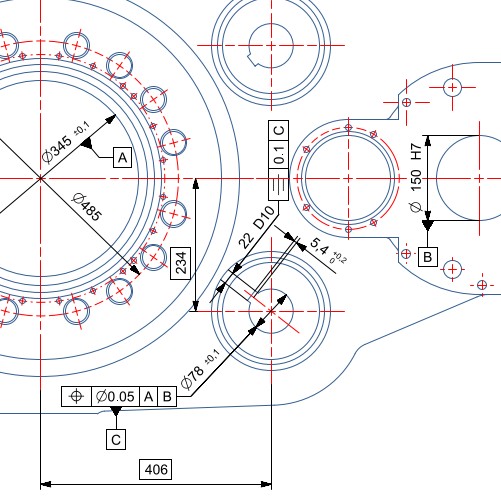

Overviews GD&T (geometric dimensioning and tolerancing) in the manufacturing of mechanical products. Topics:

- Brief history of tolerancing

- How are tolerances measured?

- How are tolerances specified?

- What is GD&T?

- GD&T Examples

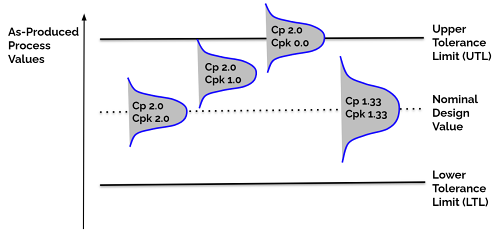

What are Cp, Cpk, and PPM in Tolerance Analysis?

What are these statistical parameters and how are they applied to tolerance analysis? Topics:

- What is Cp?

- What is Cpk?

- What is PPM?

- Cp, Cpk, and PPM in tolerance analysis

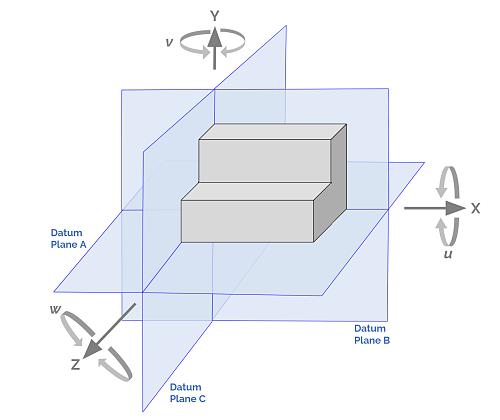

Why are GD&T Datums Important to Tolerance Analysis?

Overviews datums and their importance to tolerance analysis. Topics:

- Types of datums

- Datum symbols and representation

- Datum systems and degrees of freedom

- Choosing datums wisely for tolerance analysis

How to Solve Multi-Hole Tolerancing Problems

This demonstration video shows how to make multi-hole tolerancing decisions that ensure a reliable fit of assembled components. Using Enventive’s Concept software and an electric busbar example, topics shown include:

- Modeling an assembly with pin in hole features

- Analyzing for assembly collision problems

- Optimizing contributor values to achieve targeted failure rate of assembled fit.